by Nick Emanuel, CropX Lead Marketing Agronomist

Nick Emanuel is the founder of CropMetrics, a company that merged with CropX in 2020. Since the merger, he has remained actively involved in product development and marketing for CropX. In addition, Nick manages his family farm in eastern Nebraska, where he grows corn and soybeans. With his expertise in both agricultural practices and technological innovation, he offers a unique perspective on the potential of variable rate irrigation technology (VRT) to optimise crop yields and promote sustainable farming practices.

The Origins of Variable Rate Technology (VRT) in Agriculture

Variable rate technology has been around for over 40 years, when Dr. Pierre Robert was the first to research variable rate fertilizer spreading back in 1983. It began on the principle that different areas of the field had different yields, thus creating different nutrient requirements for optimal yields. Then in the early 1990s came the yield monitor on combines and introduced an entirely new breakthrough on mapping this known yield variability throughout the field. The ability to pair this yield data with grid soil sample results created opportunities to develop variable rate input adjustments to improve yields and save on input costs. Although the technology made agronomic and economic sense, it was slow to adopt in the early years due to complexity of the early versions of precision agriculture software and hardware controllers. Advancements throughout the 2000s on both software and hardware allowed more growers to take advantage of these variable rate opportunities, however, it was still not adopted by the majority. Aside from plant nutrition and soil fertility, other inputs began to be variable rate applied such as seeding populations, fungicides and plant growth regulators. But there was still one input overlooked, primarily again because of the lack of adequate software and hardware options to effectively manage this input. This input can have the largest influence on crop yield each year, while creating the most yield variability across the field. Whether we are receiving it naturally via rainfall, or applying irrigation in-season to supplement crop water demands, WATER is the main driver of yield potential.

Early Struggles and Adoption Barriers of Precision Agriculture

When I began my personal quest with variable rate on my irrigated family farm in eastern Nebraska, the goal was to maximize yield potential on every acre in hopes of driving overall profitability on each field. We had done the traditional grid soil sampling with VR dry spread fertilizer, but it was time to next it to the next level combining seeding and nitrogen. It was the early 2000s and these two inputs received much attention for controlling yield potential. I spent countless hours analyzing several years of yield data using high powered desktop software to eventually create multiple year average yield zones that would represent the high and low yielding zones throughout each field. Now I was excited, we were going to push yields on our better ground to heights we’ve never seen and save input costs on the lower producing zones of the field. Win-win, I thought… Arriving to harvest, I anxiously awaited the yield results and maps to see the success of our trials. But in the end, it seemed as if there were minimal yield improvements and variability was still present with some cases increasing in variability. This was a common challenge with the early adopters of variable rate, challenged with seeing the immediate payoff. Something was still missing.

The Revelation of Soil Moisture Sensing

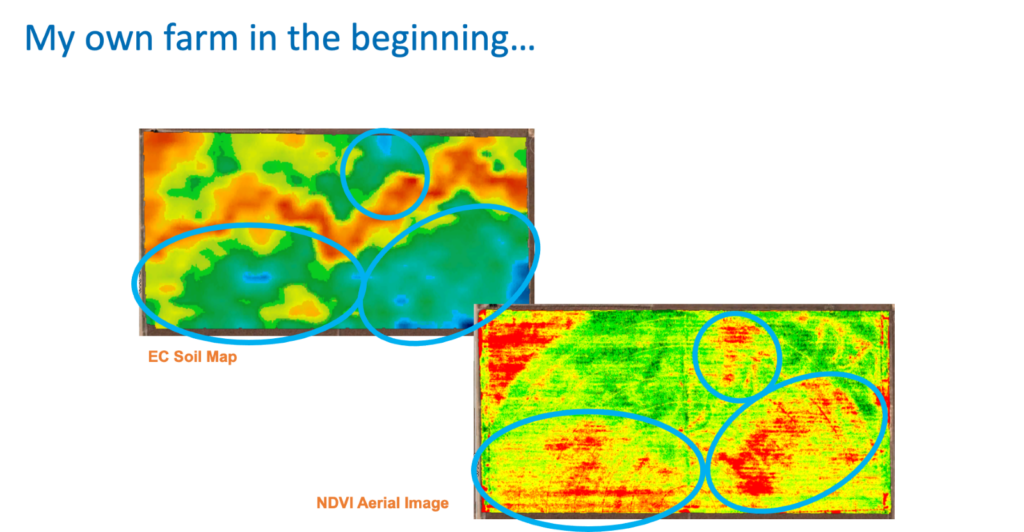

Around this same time, we started testing capacitance soil moisture probes. This was eye opening with a new level of detailed information received from multiple sensor depths and frequent data uploads throughout the day, compared to the traditional watermark sensors. Not only was irrigation scheduling improved, but we were able to better understand crop water demands at each growth stage throughout the season. The data would begin to reveal rooting depth activity, and where we were and were not utilizing water efficiently in the soil profile. Also, during this time, I started to map fields with electrical conductivity (EC) sensors hoping to unveil something more we were missing on variable rate applications. And this is when the dots started to connect. In-season aerial imagery identified lower crop health in the heavier soils. These were the same heavier soils that were supposed to have the highest yield potential and were the zones I was pushing with seeding and fertilizer variable rates. This eye-opening data is where we started to better understand true water optimization. We learned that as we would irrigate one flat rate with the center pivot, it would be over-watering or underwatering the different soil types throughout the field and ultimately nullifying any opportunity we had with the other variable rate applications. A major reason why we were not seeing end of season yield results from these applications.

Understanding Spatial Optimization: The Majority Acre Principle

As we continued to better understand the varying water requirements in each management zone throughout the field, we started to develop two core principles based around water optimization, and both would hinge on the idea of spatial optimization. When a field has variability of any kind, then there is potential for an area in the field to represent perfect conditions and perfect results. Unfortunately, that could be 1% of the area or less. But what that tells us is that through better conditions and management, a better result could have been achieved on all areas. Spatial optimization is therefore creating a situation where we transfer the perfect conditions from the 1% of the area to a bigger portion of the field. We can ultimately achieve this by focusing our water application, nutrition, management and all agronomy on the majority acre type of the field to begin with. By maximizing productivity on the majority acre of the field, we can maximize profitability on the whole field. So where did we have it wrong? In the early days of irrigation, a common approach was to start applying water when the crop first showed signs of stress. However, that stress could be in a lighter soil type of the field that may constitute a small number of acres across that entire field. When we irrigate for this lighter soil type, we are continually over-watering the rest of the field and thus limiting our overall potential. The first principle of water optimization relies on identifying and irrigating for the majority acre. This ensures we are applying the right rate at the right time for optimal crop development in season, in turn allowing the crop better nutrient use efficiency and maximum yield potential. Again, this is the best opportunity to excel our whole field profitability, which is what every farm and field should be focused on. This can be achieved by placing a moisture probe, such as the CropX Soil Moisture Sensor, in the majority acre management zone, and making more informed irrigation decisions with this data.

Advancing with Variable Rate Irrigation (VRI) Technology

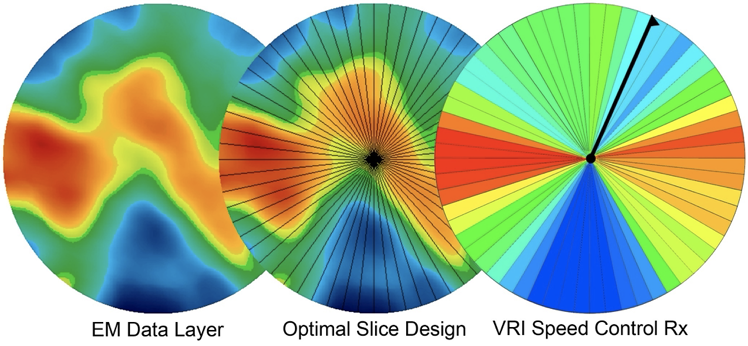

The next step in spatial optimization is the attempt to transfer the idea of optimal irrigation to other parts of the field, ideally watering each acre dependent on its individual water holding capacity and plant water demands. In 2009 I founded CropMetrics and released the first commercially available Variable Rate Irrigation (VRI) software on the premise of this concept. Most center pivots on the market today can adjust rates at varying angles around the circle. Many, including any pivot with a telemetry monitoring device, can be programmed very easily to adjust the speed automatically as the pivot turns to apply varying amounts of water to compensate for the field’s variability. Utilizing advanced, but easy to use software, such as the CropX (formerly CropMetrics) agronomic farm management system, growers can now create VRI prescriptions which can then be uploaded to these pivot controllers. The software allows the user to customize management zones for each field using any type of underlying data layers available for the field, all in a simple step by step online process. VRI provides an opportunity to adjust irrigation rates based on detailed soil type (using electrical conductivity (EC)), topography, yield or as-applied machine data. It can create scripts from real-time in-season imagery to account for the variability as it happens. There is nothing more important in variable rate than optimizing your water on each acre first. Otherwise, disappointing results can arise when attempting to variable rate other inputs without focusing on water also.

An Integrated Approach to Input Efficiency

CropX software now provides the capability to create VRA planting and fertilizer scripts using the same management zones as VRI to take your input efficiency to the next level through an integrated systems approach, adjusting all input to the same zones. All in one easy-to-use platform! But none of this can be achieved effectively without starting with spatial optimization which begins with water management. VRI technology allows the grower to optimize irrigation applications spatially across the field, resulting in improved yields, increased nutrient use efficiency, conserving our most valuable natural resource while maximizing profitability.